Introduction

From insoles to jewelry, 3D printing’s disruptive impact now extends to revolutionizing fashion industry and manufacturing. This emerging technology promises custom-fit clothing based on exact body measurements while enabling on-demand production with less waste. Though scaled adoption faces hurdles in print speed, object size, multi-material capabilities, and potential regulation, localized and sustainable 3D printing could fundamentally transform today’s “fast fashion” practices towards more eco-conscious innovation meeting real-time consumer demand.

What Is 3D Printing and How Is It Used in Fashion INDUSTRY?

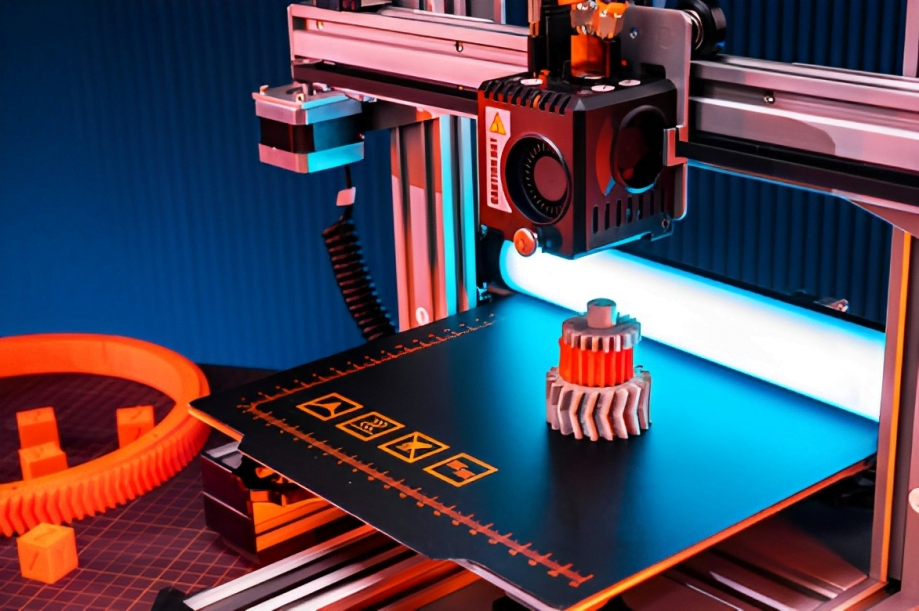

Also known as “additive manufacturing,” 3D printing works by precision-depositing thin slices of material in layers based on digital 3D design files. Rather than traditional subtractive techniques reliant on cutting, stitching or otherwise removing material in clothesmaking, this approach directly fuses together physical structure from the virtual blueprints. Depending on the specific printer type and underlying process, finished objects can incorporate plastics, metals, living cells and more into their final composition.

For fashion Industry, some current applications concentrate around decorative accessories, footwear components and costumes along with small textile swatches or embroidery pieces. High-end bespoke couture brands also utilize 3D printing in custom garment creation. However, as this technology continues rapidly maturing, it aims to deliver:

✅ Fully customized apparel sizing/fits tailored to unique body measurements

✅ Expanded personalization and embellishment flexibility

✅ Simplified small-batch production cycles

Most Common Methods for 3D Printing Clothing

| Common 3D Printing Technologies | Typical Materials Used |

|---|---|

| Fused Deposition Modeling (FDM) | Thermoplastics like ABS, PLA |

| Stereolithography (SLA) | Photosensitive resin |

| Selective Laser Sintering (SLS) | Thermoplastic powder (e.g. nylon) |

| Multi-Jet Fusion (MJF) | Various plastics |

Full automation of end-to-end seamless 3D printed clothing without assembly does face continued limitations around speed, object size, materials availability and final finish quality.

Customization Potential for Bespoke Apparel Design

As 3D printing advances, one monumental opportunity lies in elevated customization – prioritizing unique traits over one-size-fits-all design uniformity.

Revolutionizing Fit via Precise Body Measurements

3D printing facilitates directly tailoring apparel patterns to an individual’s specific measurements for a superior fit. Software digitization enables flexibility in accommodating different heights, shapes and proportions accurately. This custom-fit potential significantly empowers groups historically underserved by limited standard sizes:

- Minorities with uniquely shaped body types

- Differently-abled consumers

- Plus-size demographics

- Children and seniors

Unlocking Personalized Style and Self-Expression

Digital 3D fashion templates also unlock potential for enhanced personal embellishments – initials, logos, meaningful graphics. Designers gain more freedom around textures and decorative touches once prohibitively expensive using conventional techniques.

No longer exclusively reserved for high-fashion clientele, thistechnology aims to bring bespoke customizable style options into mainstream accessibility.

Optimizing Small-Scale On-Demand Manufacturing

3D printing promotes leaner production methods for apparel, lowering startup costs.

This bar graph illustrates projected annual units shipped for 3D printing in retail clothing from 2021 to 2030. Anticipating significant growth, starting at 124 thousand units in 2021 and reaching 7.1 million by 2030. The data reflects exponential projections, highlighting the transformative potential of 3D printing in retail clothing manufacturing in Fashion Industry.

Reshaping Globalized Supply Chains

Speculative seasonal demand forecasting used widely today frequently yields chronic excess inventory even for fast fashion brands. By printing garments to order aligned with real-time sales data instead, retailers can minimize waste. Localized fabrication also mitigates international shipping miles tied to offshore outsourcing.

Empowering Emerging Talent

By eliminating prohibitive minimum order quantities for design testing, 3D printing offers flexibility for smaller designers to validate creative concepts via limited initial launch volumes. Adjusting based on customer feedback proves faster and lower risk than upfront investments in mass production. Reducing financial barriers to trial bold ideas or sustainable materials ultimately promotes more diversity of creative participants.

However, additive techniques do still generally fall behind conventional methods for simplicity, speed and per unit cost at extremely high volume production levels. Most mass clothing fabrication currently focuses on hybrid methods combining 3D printed textiles subsequently hand-assembled into finished garments.

Sustainability Benefits

Closed-Loop Recycling Systems

Recapturing used plastics and fabrics to convert into 3D printing filaments minimizes textile disposal. Continued material innovation around renewable biopolymers hopes to further improve ecological impact as adoption advances. However, increased energy demands at larger scales remains an area needing further study.

Environmental Sustainability Potential

Localized distributed manufacturing with recyclable materials also renders 3D production pivotal for promoting sustainability against today’s prevalent throwaway fast fashion waste crisis.

Future Outlook

In the near term, specialty fashion categories like athleticwear, medical devices and entertainment costumes seem poised for imminent 3D manufacturing disruption. However over a longer timeframe, advanced systems and materials innovations promise increasingly mainstream integration potential. Both HP and Carbon spearhead pushing achievements in finished textiles printing capabilities — even intricate leathers, silk and hemp prove possible already. The vision looks toward distributed neighborhood microfactories someday replacing sew shops.

As prices fallsquarely into middle class affordability over the next decade, personalized customizationstands to rewrite consumer expectations around self-expression and apparel shopping. While substantial research gaps persist, additive technologies now bear undeniable momentum across many fashion niches and segments. Global fashion brands ready themselves to react appropriately to this inevitable oncoming transformation.