Introduction:

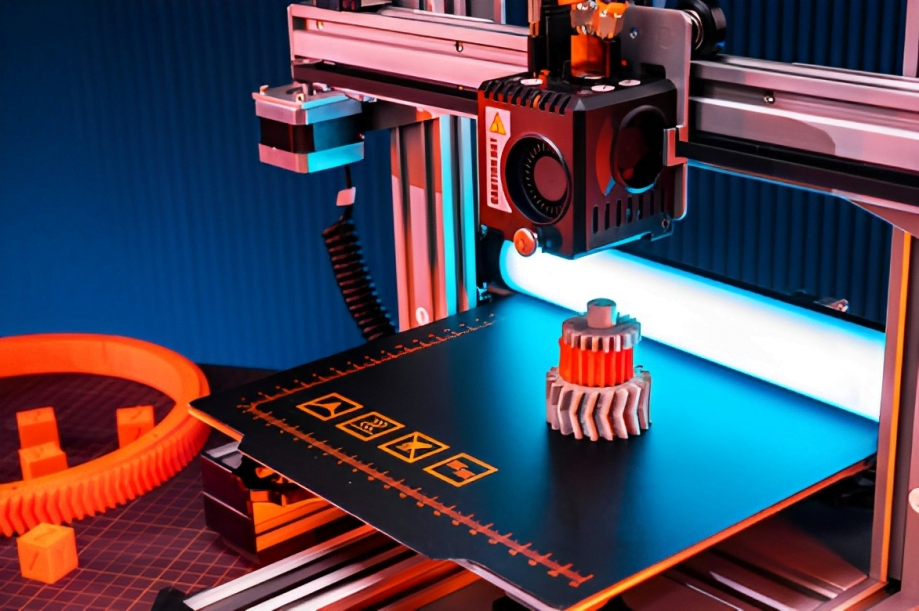

The 3D printing process relies on taking a digital 3D model file, and converting it into physical layer-by-layer instructions which your 3D printer can then follow to build the real object from your design. But how does one go from a 3D file on your computer to that set of printer-friendly instructions? This is where slicing software, often referred to as a “slicer”, comes in – it is the bridging programs that converts your 3D model into a printable format.

Equipped with these basics you’ll understand the role a 3D slicer plays in the printing process, and be set to dig deeper into 3D printing success!

What Does a 3D Slicer Do?

A 3D slicer, as the name suggests, slices up your model into steps for your 3D printer. Specifically, it transforms the digital design into a format called GCode that contains necessary printing instructions for your specific 3D printer machine.

Some of the key functions of a slicer include:

- Interpreting the STL or OBJ file of your 3D model design

- Slicing the model into layers based on chosen layer height setting

- Generating the GCode toolpaths that tell your nozzle where to move and extrude material for each layer and feature

- Adding key printing settings like infill patterns, bed adhesion aids like rafts or brims if required, and computer-generated support structures for overhangs

- Allowing optimization and tweaking parameters like print speed, temperature, retraction etc. for your specific machine and filament material

Without this step of using a slicer to preprocess and digitally prepare your model into the printer-friendly GCode instruction set, you couldn’t actually fabricate your creations!

Common Slicer Features & Settings

Now that understand what a slicer does at a high level, what are some of the core features and customizations these tools actually provide control over? Here is an overview of some of the most important 3D slicer settings and capabilities:

Print Processing Parameters

- Layer height: Determines vertical resolution and detail. Smaller layer height = smoother surfaces but longer print.

- Infill % and pattern: Controls interior fill, density vs print time/material tradeoff

- Number of perimeters/shells: Additional outer shells improve strength

- Supports: Generate structures to brace overhangs and tricky geometry

- Adhesion aids: Brim, raft helps first layer stick to the print bed

Filament & Machine Settings

- Nozzle and bed temp: Critical to get right for your specific plastic filament type

- Print speeds: Faster lowers time but can impact quality and accuracy

- Cooling settings: Fan speeds, when active etc.

- Retraction: Prevents “stringing” by controlling filament withdrawal

Advanced Features

- Dual extrusion: For multi-material models and prints

- Custom support structures: Specify overhang angles, geometry etc

- GCode analysis & optimization: Manage file size, visualization

As you gain more experience, you’ll learn how tuning the above parameters for your specific printer and material dialed in makes all the difference in final model accuracy, strength and print quality.

Popular Slicing Software Options

Now that we have covered what a 3D slicer does and the core settings it provides control over, what are the popular options on the market? Here we highlight a few of most common 3D printing slicing tools:

Cura

- Free, open source software maintained by Ultimaker

- Easy interface ideal for beginners

- Broad hardware compatibility and an active user community updating machine profiles

Simplify3D

- Simplify 3D is a Paid software but comes loaded with advanced features

- Support editing, dual extrusion, GCode analysis/optimization

- Print quality is excellent, but has a steep learning curve

IdeaMaker

- Free slicing option focused on high-quality results

- Optimized profiles for popular printers preloaded

- Supports common file repair and editing tools

There is healthy competition in the 3D printing software space given the rising popularity of the technology. The above programs focus primarily on laser-based FFF/FDM printing that use thermoplastics, but you can also find specialized slicers if you work with SLA, DLP, metal sintering methods. While features and usability varies, any mainstream slicer will output the GCode your printer needs.

Choosing the Right 3D Slicer

With those main options summarized, how do you choose the best 3D slicer for your needs as a beginner?

For most hobbyists starting out, a free and widely used program like Cura hits a sweet spot. It has great hardware support, starter-friendly settings menu, and an active community to learn from while allowing plenty of room to grow into more advanced features when ready.

Getting Started With Your First 3D Print!

Once you’ve installed your selected slicer software, how do you prep files and get started actually printing with it?

With profile presets and suggested settings in most slicers today, you’ll be able to get surprisingly good starter prints with just default parameters. But over time you’ll learn how adjustments to temperature, speed, cooling etc. can take you to the next level!

Now that you know what a 3D slicer is and how to get started slicing models, stay tuned for our next guides going deeper into popular slicers! We’ll provide specific tips on optimizing Cura, Simplify3D, IdeaMaker and more for incredible prints.