Table of Contents

ToggleINTRODUCTION

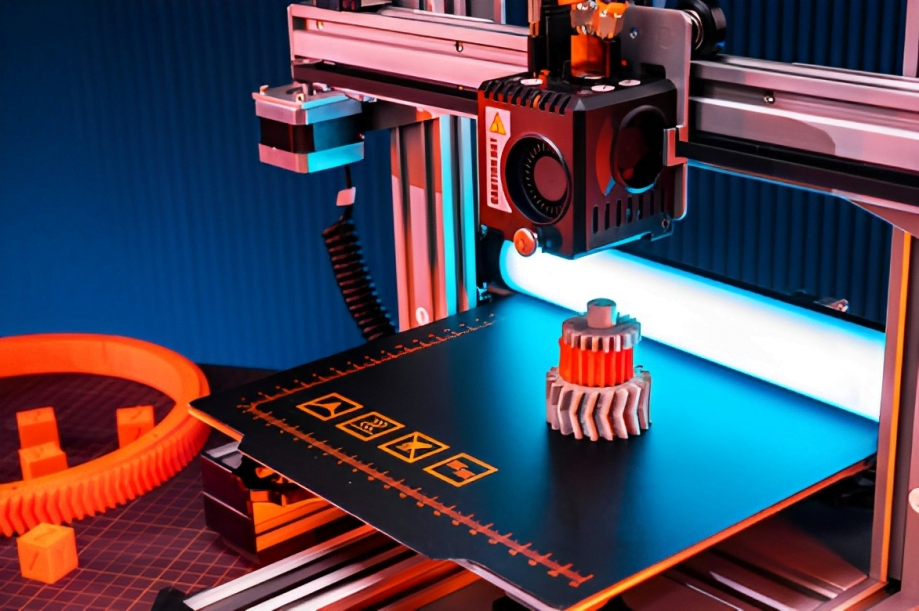

In past years, 3D printing has increased in popularity, offering a number of benefits to hobbyists and professionals, alike. While the concept of 3D printing is fascinating and appealing, buying a 3D printer can be extremely expensive for many people. Building your own 3D printer, on the other hand, can be a low-cost solution with numerous potential benefits.

Building a 3D printer from the scratch can be difficult,but it has become much more accessible in recent years. With the availability of low-cost parts, in-depth tutorials, and community assistance, an increasing number of people are deciding to build their own 3D printers rather than purchasing pre-built models. One of the key advantages of building your own printer is the potential cost savings.

You may significantly reduce the overall cost of a 3D printer by sourcing your own parts, making your own frame, and using open-source software. This makes 3D printing more accessible to budget-conscious enthusiasts, students, and professionals, without losing quality and utility but will need some basic skills.

Throughout this article, we will explore the advantages and disadvantages of building and buying a 3D printer, as well as analyze the expenses associated with each alternative. We will also share advice and resources to help you in making an informed decision and get started with 3D printing . This guide will help you choose the best path for your needs, whether you want to save money, personalize your printer, or simply enjoy the process of constructing your technology. So let’s dig in and learn about 3D printing!

Building a 3D Printer: Pros and Cons

Creating a 3D printer from nothing can be a gratifying experience, but it is not without its difficulties. Here are some advantages and disadvantages to consider before going on your very first DIY 3D printing journey.

PROS:

- Customizability: When you build your own printer, you may tailor it to your exact needs and tastes. You can select the frame, components, and software that best meet your needs.

- Savings: As previously said, creating your own printer can save you a significant amount of money when compared to purchasing a pre-built machine. This is especially true if you have some of the required tools and equipment.

- Experiential learning: Constructing a 3D printer from the ground up is an excellent way to learn about the technology and acquire practical experience with electronics and mechanics.

- Satisfaction: There is a sense of accomplishment that comes with developing your own technology, especially when it begins to produce successful prints.

CONS:

- Technical knowledge: Building a 3D printer required some technical knowledge and skills, such as expertise in electronics, programming, and mechanics. don’t panic there are numerous tutorials and materials available, newcomers may face a steep learning curve

- Time-consuming: Constructing a 3D printer from scratch takes time and demands patience and attention to detail. It could take weeks or even months to complete.

- Troubleshooting: Because you’ll be creating your own printer, you’ll be in charge of diagnosing any problems that develop. This can be difficult and unpleasant, especially if you are unfamiliar with the technology.

You can watch complete Guide here.

Buying a 3D Printer: Pros and Cons

If building a 3D printer from scratch sounds intimidating, you may be considering purchasing a pre-built model instead. Here are some of the pros and cons to help you decide if this is the right option for you.

Pros:

- Convenience: Buying a pre-built 3D printer is the easiest and most convenient option. You can simply unbox it, set it up, and start printing right away.

- Technical support: Most pre-built 3D printers come with technical support and a warranty, which can be helpful if you run into any issues.

- Time-saving: Since pre-built 3D printers come fully assembled, you’ll save a lot of time compared to building your own printer.

Cons:

- Cost: Pre-built 3D printers are generally more expensive than building your own printer, and you may be paying for features that you don’t need.

- Limited customizability: While some pre-built printers allow for some customization, you’re still limited by the design and components that come with the printer.

- Quality control: With pre-built printers, you’re relying on the manufacturer’s quality control and component selection. This can result in lower quality prints or a shorter lifespan for the printer.

Overall, purchasing a pre-built 3D printer may be the right option for those who prioritize convenience and support over cost and customizability. However, it’s important to do your research and choose a reputable manufacturer with a good track record of quality and customer service.

Cost Comparison: Building vs Buying a 3D Printer

When considering the costs of building or buying a 3D printer, it’s important to take into account the initial investment as well as ongoing expenses such as maintenance and repairs. Here are some of the costs associated with each option:

Building a 3D Printer

Materials Required:

- Frame and Hardware.

- Etruder.

Frame and hardware:

$100-$300 depending on the size and complexity of the printer.

Electronics:

$50-$200 for the controller board, motors, and wiring.

you can check a cheap Controller board here.

Extruder and hot end:

$50-$150 for a basic setup.

Power supply:

$20-$50 depending on the wattage needed.

you can buy cheap power supply here.

Software:

Free open-source software is available for 3D printing.

you can use this software it is free and easy to use.

Total estimated cost:

$220-$700

Buying a 3D Printer

Entry-level printer:

$200-$500 for a basic pre-built model.

Mid-range printer:

$500-$1,500 for higher-quality prints and additional features.

High-end printer:

$1,500-$5,000 for professional-grade printing.

Additional costs:

- Filament: $15-$50 per kilogram.

- Maintenance and repairs: Varies depending on the printer and any issues that arise.

- Upgrades and accessories: Optional add-ons can add up to hundreds or thousands of dollars.

- Total estimated cost: $200-$5,000+

Generally, building your own printer is less expensive than acquiring a pre-built machine, especially if you already have some of the necessary tools and equipment. Yet, it’s vital to remember that creating a printer from the ground up takes time and technical skills. Purchasing a pre-built printer, on the other hand, maybe more convenient and come with technical support, but it may be more expensive and limit your customizabilit

CONCLUSION

In conclusion, the decision to build or buy a 3D printer ultimately depends on your personal preferences, technical abilities, and budget. Building your own printer can save you money and allow for greater customization, but requires time and expertise. Purchasing a pre-built printer is more convenient and may come with technical support, but can be more expensive and limit your customization options.

If you decide to build your own 3D printer, there are numerous tutorials and resources available online to guide you through the process. Similarly, if you choose to purchase a pre-built printer, it’s important to do your research and choose a reputable manufacturer with a good track record of quality and customer service.

Regardless of which option you choose, 3D printing is a fascinating technology with limitless potential for creativity and innovation. We hope this guide has been helpful in assisting you in making an informed decision and getting started with 3D printing on a budget.

Very informative

Thanks