Introduction

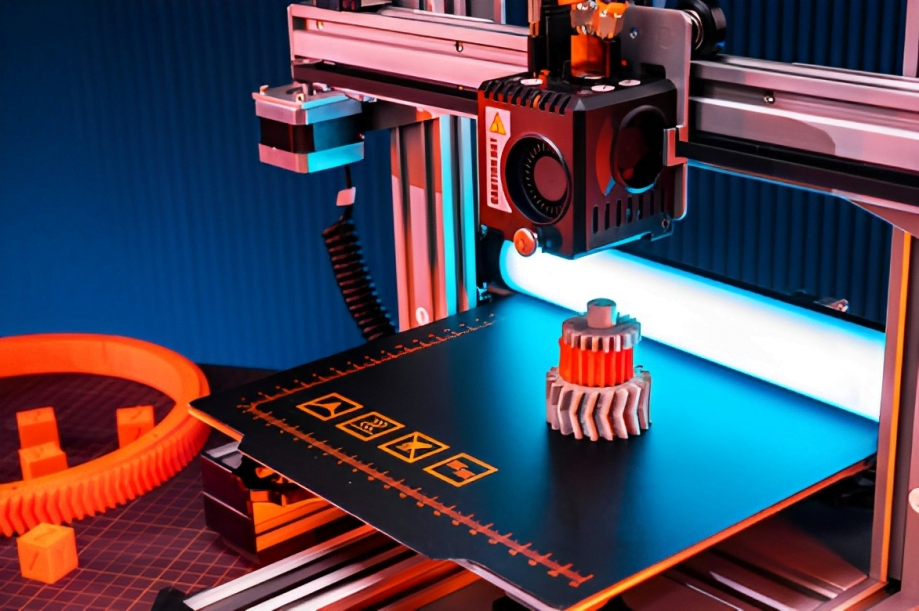

In recent years, 3D printing has emerged as a revolutionary technology with the potential to transform various industries. Also known as additive manufacturing, 3D printing allows for the creation of three-dimensional objects by layering materials in a precise and controlled manner.

This process has opened up new possibilities in fields such as rapid prototyping, cost-effective production, and fast production.

One of the key advantages of 3D printing is its ability to rapidly create prototypes. Traditional methods of prototyping can be time-consuming and expensive, often requiring complex tooling and lengthy production cycles.

With 3D printing, designers can quickly bring their ideas to life by creating physical prototypes directly from digital files. This not only accelerates the product development process but also allows for more iterations and improvements before finalizing a design.

Furthermore, 3D printing offers cost-effective production solutions. By eliminating the need for traditional manufacturing processes that require extensive tooling and setup costs, companies can reduce their expenses significantly.

This makes it particularly attractive for small businesses or startups looking to bring their products to market without breaking the bank.

In addition to cost-effectiveness, 3D printing enables fast production turnaround times. Traditional manufacturing methods often involve long lead times due to factors such as Material sourcing, Transportation logistics, and Complex assembly processes.

With 3D printing, objects can be produced on-demand and locally, reducing lead times considerably. This opens up opportunities for just-in-time manufacturing and customization options that were previously unattainable.

As we delve deeper into this section on understanding the power of 3D printing technology, we will explore its various applications across industries such as healthcare, automotive, aerospace, consumer goods, and more. We will also examine how this technology is driving innovation and transforming traditional manufacturing processes.

So join us on this journey as we uncover the immense potential that lies within the realm of 3D printing and discover how it is reshaping the way we design, produce, and create.

1.Rapid Prototyping

Rapid prototyping is revolutionizing the product development process by significantly speeding up the time it takes to bring a product from concept to market. With the advent of 3D printing technology, designers and engineers can now quickly create physical prototypes of their designs, allowing for faster design iteration and a more efficient iterative design process.

Gone are the days of waiting weeks or even months for a prototype to be manufactured. With rapid prototyping, designers can now produce functional prototypes in a matter of hours or days. This not only saves valuable time but also enables them to test and validate their designs much earlier in the development cycle.

The benefits of rapid prototyping extend beyond just speed. By being able to physically interact with a prototype, designers can gain valuable insights into its form, fit, and functionality. This allows for quick adjustments and refinements, ensuring that the final product meets all requirements before moving into production.

Additionally, rapid prototyping enables companies to reduce costs associated with traditional manufacturing methods such as tooling and molds. It eliminates the need for expensive upfront investments in production equipment, making it an attractive option for startups and small businesses looking to bring their ideas to market without breaking the bank.

Ultimately, rapid prototyping accelerates the entire product development process, leading to faster time-to-market and giving companies a competitive edge in today’s fast-paced business landscape. By leveraging this innovative technology, designers and engineers can iterate on their designs more quickly than ever before, resulting in better products that meet customer needs efficiently.

2.On-Demand Manufacturing: Eliminating Inventory and Reducing Costs

On-demand manufacturing, also known as just-in-time production, is revolutionizing the manufacturing industry by eliminating the need for excessive inventory and reducing costs. One of the key technologies driving this shift is 3D printing.

Traditional manufacturing processes often require large amounts of inventory to be stored, resulting in significant costs associated with storage space and management. On the other hand, on-demand manufacturing allows products to be produced only when they are needed, minimizing the need for inventory.

By utilizing 3D printing technology, manufacturers can quickly produce customized products without the need for expensive molds or tooling. This not only saves time but also reduces costs associated with traditional manufacturing methods.

Furthermore, on-demand manufacturing enables businesses to respond swiftly to changing customer demands. Instead of waiting for weeks or months for a product to be manufactured and shipped from a distant location, customers can receive their customized products in a matter of days or even hours.

The elimination of excess inventory and reduced lead times result in significant cost savings for businesses. Without the need for large warehouses filled with unsold products, companies can allocate their resources more efficiently and focus on meeting customer demands in real-time.

In conclusion, on-demand manufacturing powered by technologies like 3D printing offers numerous benefits such as reduced costs, improved inventory management, and faster response times. As businesses continue to adopt these innovative approaches, we can expect to see a transformation in how products are manufactured and delivered in the future.

3.Supply Chain Optimization: Streamlining Production and Distribution

Supply chain optimization plays a crucial role in streamlining production and distribution processes. One emerging technology that has the potential to revolutionize supply chains is 3D printing. By leveraging this technology, companies can significantly reduce lead times and costs associated with traditional manufacturing methods.

One of the key benefits of 3D printing is its ability to enable localized production hubs. Instead of relying on centralized manufacturing facilities, companies can establish smaller production centers closer to their customers. This not only reduces transportation costs but also allows for faster delivery times.

Furthermore, 3D printing enables inventory consolidation by eliminating the need for large warehouses and excessive stockpiling. With on-demand manufacturing capabilities, companies can produce items as needed, minimizing the risk of excess inventory and associated carrying costs.

In addition to 3D printing, efficient logistics play a vital role in optimizing the supply chain. By implementing advanced tracking systems and utilizing data analytics, companies can identify bottlenecks and inefficiencies in their distribution networks. This allows for better route planning, improved resource allocation, and ultimately reduced transportation costs.

Overall, supply chain optimization through technologies like 3D printing and efficient logistics not only saves time and money but also enhances customer satisfaction by ensuring timely delivery of products. As businesses continue to adopt these strategies, we can expect to see significant improvements in production efficiency and streamlined distribution processes.

4.Tooling and Jig Creation: Minimizing Costs and Production Time

In the realm of manufacturing and production, tooling and jig creation play a crucial role in minimizing costs and production time. One innovative technology that has emerged as a game-changer in this field is 3D printing. By leveraging additive manufacturing technology, companies can significantly reduce both time and money spent on tooling and jig creation.

Traditionally, producing jigs and tools required complex machining processes that were not only time-consuming but also expensive. However, with 3D printing, manufacturers can now create custom jigs and tools quickly and at a fraction of the cost. This technology allows for the precise fabrication of intricate designs, eliminating the need for multiple components or assembly.

One significant advantage of using 3D printing for jig creation is its ability to optimize tooling. Manufacturers can leverage the flexibility of additive manufacturing to design jigs that are tailored to specific production needs. This optimization leads to improved efficiency, reduced waste, and enhanced overall productivity.

Furthermore, utilizing 3D printing for tooling offers opportunities for inventory consolidation. Instead of maintaining large inventories of various jigs and tools, manufacturers can simply print them on-demand when needed. This approach minimizes storage requirements while ensuring that the right tools are available at the right time.

Additionally, efficient logistics can be achieved through 3D printing hubs strategically located near production facilities. These hubs serve as centralized locations where jigs and tools can be printed as required.

By reducing transportation costs and lead times associated with traditional supply chains, manufacturers can streamline their operations further.

In conclusion, 3D printing revolutionizes tooling and jig creation by minimizing costs and production time. The ability to optimize designs, consolidate inventory through on-demand printing, and establish efficient logistics networks all contribute to increased efficiency in manufacturing processes.

As this technology continues to evolve, it holds immense potential for transforming various industries by offering cost-effective solutions for tooling needs.

5.Customization and Personalization: Meeting Unique Customer Needs

In today’s highly competitive market, customization and personalization have become key factors in meeting the unique needs of customers. With advancements in technology, particularly the emergence of 3D printing, businesses now have the ability to create customized products that cater to individual preferences.

One of the most significant advantages of utilizing 3D printing technology is the ability to produce personalized designs. This allows customers to have a say in the design process, ensuring that their preferences and requirements are met. Whether it’s a custom-made piece of jewelry or a tailored clothing item, 3D printing enables businesses to offer unique products that resonate with their customers on a personal level.

Moreover, customization goes beyond just aesthetics. It also extends to providing tailored solutions for specific needs. Businesses can leverage 3D printing technology to create products that are specifically designed for individual customers based on their unique requirements. This level of customization not only enhances customer satisfaction but also helps businesses stand out from competitors by offering solutions that truly address customer pain points.

By embracing customization and personalization through technologies like 3D printing, businesses can create a more personalized and engaging experience for their customers. This not only fosters brand loyalty but also opens up new opportunities for growth and innovation in an increasingly customer-centric marketplace.

cONCLUSION

In Summary, 3D printing revolutionizes manufacturing by;

- Expediting rapid prototyping

- Enabling cost-effective on-demand production

- Optimizing supply chains

- Minimizing tooling costs

- Facilitating unparalleled customization

This transformative technology not only accelerates processes but also enhances efficiency, reduces expenses, and empowers businesses to meet evolving market demands with unprecedented agility. The diverse applications of 3D printing underscore its pivotal role in reshaping industries, promising a future where innovation and cost-effectiveness go hand in hand.