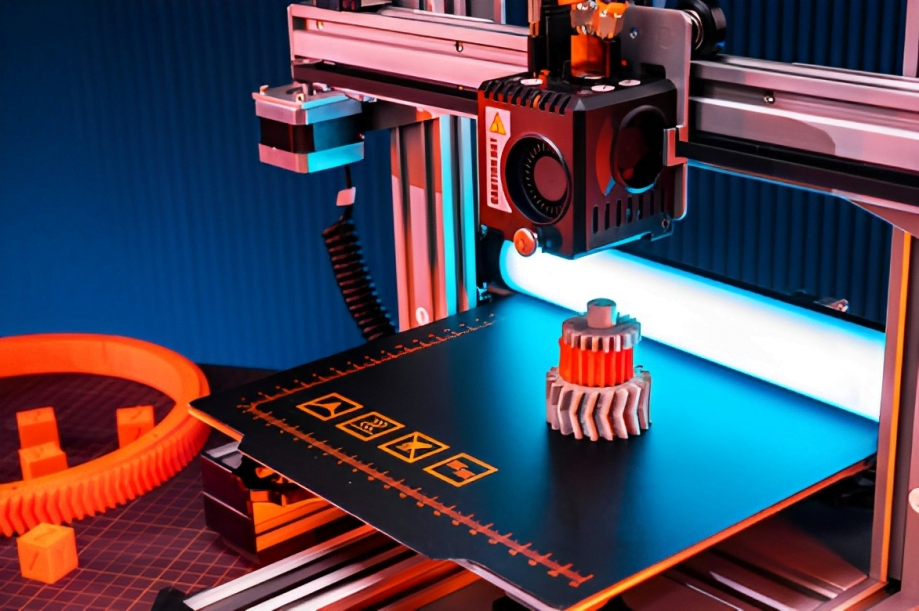

The extruder is arguably the most important component of a 3D printer. This is the part that turns raw plastic filament into the finished print by precisely depositing it layer-by-layer. Understanding how extruders work and the different types available can help you get the most out of your 3D printer.

What Does an Extruder Do?

In simple terms, an extruder feeds filament to the hot end where it melts, then applies pressure to force the molten plastic through the nozzle onto the print bed. This action is very similar to squeezing toothpaste out of a tube.

The filament enters the cold end of the extruder and is pulled into the hot end by the extruder gears or drivewheel. The hot end heats up the plastic to its melting point so it can flow smoothly. As more filament enters, pressure forces the molten plastic out of the nozzle. By coordinating the movement of the print head with the rate of extrusion, designs are built up layer by layer.

Key Extruder Components

There are a few vital components that make up an extruder:

- Drive Mechanism: Feeds the filament into the hot end through gears, wheels or other methods. This controls the rate of extrusion.

- Hot End: Heats up and melts the plastic so it can flow through the nozzle. Usually made of brass or copper with integrated heating elements.

- Nozzle: A tiny openings (typically 0.2mm to 0.8mm) that shapes the flow of molten plastic onto the print bed. The smaller the opening, the finer the print resolution.

- Cooling Fans: Fans mounted near the hot end keep the stepper motors and extruder assembly from overheating. These are crucial for some designs.

Types of Extruders

There are several common extruder designs used on 3D printers:

Direct Drive Extruders

This is the most basic type, with a gear drive that is mounted right on the hot end. Filament travels in a straight path from the feeder gears directly into the hot end. Direct drive extruders provide excellent force and feedback needed for flexible and specialty filaments. However, they can be heavy on print heads.

Geared Extruders

Similar to direct drive, but the motor and drive gears are offset using a gear train instead of being mounted on the hot end. This helps reduce weight while still providing plenty of drive force.

Bowden Extruders

With this popular design, the motor assembly is separate from the hot end which allows very lightweight print heads. Filament travels through a thin PTFE “Bowden” tube between the drive unit and hot end. However, flexibles can be tricky with Bowdens since the tube adds friction.

Dual Drive Extruders

Instead of using one drive gear, dual drive units employ two opposing gears that “pinch” the filament between them for improved grip and feed reliability. This style works very well with tricky materials like flexible.

Material Extruders

Unusual extruders like the Laserwire Lab CW1 allow you to experiment with unique materials such as clay, icing sugar, chocolate, silicone and more. If you want to 3D print using something beyond normal filaments, this type is for you.

Key Extruder Specifications

- Maximum Temperature: The highest temp the hot end can reach, usually over 230°C.

- Compatible Filament Diameters: Common sizes are 1.75mm and 3mm. Not all extruders work with both diameters.

- Retraction Distance: Important for filaments like PLA that can ooze. Measures in mm how far filament is reversed to prevent oozing.

- Volumetric Extrusion Rate: Details the cubic mm per second that can be extruded, defining print speed limits.

Extruder Maintenance and Upgrades

Like any machine component, extruders need regular inspection and maintenance for optimal longevity and performance. Here are some recommended practices:

- Inspect gear teeth for wear and replace if degraded. Dual drive gears wear 2x faster.

- Clean hot end jamming using “cold pulls” and nozzle cleans.

- Clip filament cleanly so it seats fully in the drive gears/wheel for good traction.

- Check for loose screws or mounts; tighten anything loose.

Popular extruder upgrades include adding dual drive capability, switching to an all-metal hot end for higher temp capability with exotic filaments, or installing a flexible filament kit for reliable printing with materials like Ninjaflex.

Picking the Right Extruder

When selecting an extruder, key choices include:

- Direct vs. remote drive. Remote can allow for lighter print heads.

- Single vs. dual/multi drive for more power and better flexible filament handling.

- Gear, wheel or hobbed bolt drive options each have pros and cons.

- Compatibility with your hot end and control electronics is essential.

- Unique capabilities like multi-material or colorful printing may be an option.

The extruder directly influences the quality and capabilities of your 3D printer. Putting thought into your choices here pays off with better prints and less headaches down the road. A good extruder optimally balances weight, functionality, and reliability.

Conclusion

As the key active component that lays down printed material, well-engineered extruders enable everything from tiny, intricate art pieces to large, functional prototypes. The varieties and options explored here all cater to different needs and applications. Whether DIY printing or using an industrial machine, understanding the heart of these 3D printing systems unlocks their full potential.