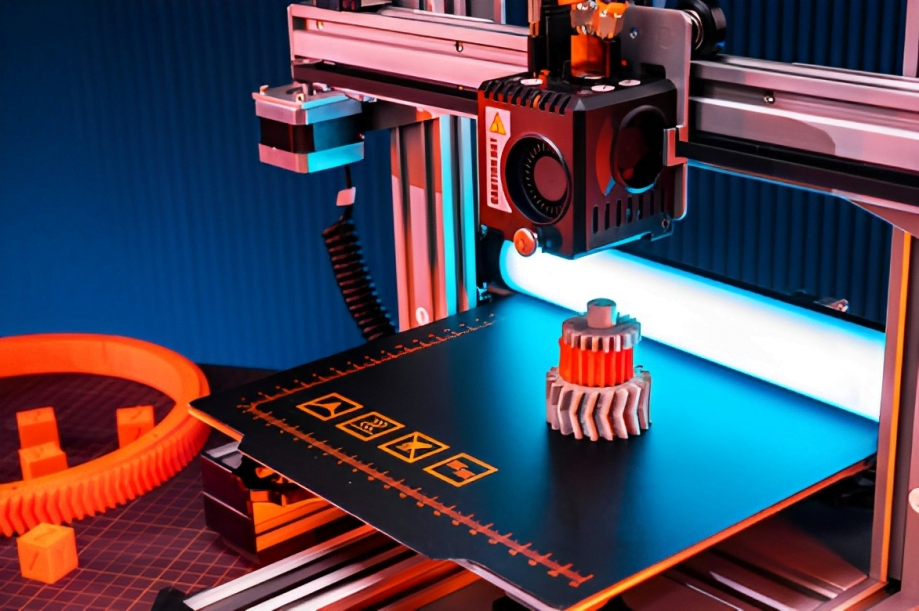

3D printing has evolved from printing small prototypes to now constructing entire houses, car parts, and even human organs. This technology is set to transform manufacturing and medicine over the next decade as more materials and applications emerge.

Wider Range of Materials for More Applications

Currently, 3D printers utilize various plastics, resins, metals, ceramics, food items and living cells. As the range of composite materials and nanomaterials expand, more industries will adopt 3D printing for mass production needs. From electronics and medical implants to pharmaceuticals, fashion and construction, 3D printing allows on-demand, flexible and cost-effective manufacturing. For example, athletic shoe soles and insoles can be tailored to fit an individual’s footprint perfectly using 3D scanning and printing. Automotive companies also utilize 3D printed injection molds to streamline production.

Bioprinting – The Future of Transplantable Organs

Bioprinting uses 3D printing and biological materials to produce living tissue and organs. Experts predict bioprinted skin, bones and cartilage will replace damaged tissues in human patients by 2030. More complex organs like hearts, lungs and kidneys will likely reach human clinical trials as well. If successful, this breakthrough could resolve the global organ donor shortage that causes 20 people to die daily in the US while waiting for an organ transplant.

3D Printing Promises to Disrupt the $12 Trillion Global Manufacturing Sector

With faster and cheaper 3D printers entering homes, schools and businesses, additive manufacturing will soon evolve from a niche market into a mainstream staple. Research indicates over 60% of Western households may own a basic 3D printer by 2030. People could print household items, toys, spare parts, tools and more from the convenience of their homes.

In addition, small-scale 3D printing stores providing services to consumers and businesses may emerge across towns worldwide. McKinsey estimates 3D printing could disrupt the $12 trillion global manufacturing sector in the next decade.

Artificial Intelligence to Unlock 3D Printing’s Full Potential

Artificial intelligence (AI) algorithms help optimize intricate 3D printing processes by enhancing speed, quality control and customization accuracy. By 2030, most commercial and industrial 3D printers will have inbuilt AI capabilities. This allows them to self-diagnose maintenance issues and adapt prints for specific applications. Combining AI and 3D printing unlocks exciting possibilities like voice-commanded printers, and fully automated production of personalized products.

The Sky’s the Limit: 3D Printing in the 2040s and Beyond

In the 2040s, 3D printing systems could achieve nano-scale resolution for molecular-level prints. 4D printing may allow printed items to self-assemble or change forms over time. But perhaps the most transformative application is bioprinting fully functional organs tailored to each patient’s biological makeup to cure diseases. Further innovations could print integrated circuits, robots, artificial intelligence systems and more without any assembly. As costs drop and adoption spreads, 3D printing has immense potential to remake global supply chains and disrupt nearly every sector from healthcare to aerospace.

| Application | Predictions by 2030 |

| Range of Materials | Wider material availability enabling more 3D printing applications across sectors |

| Bioprinting | Multiple 3D printed tissues and organs ready for human transplantation |

| Industry Adoption | Over 60% household penetration of basic 3D printers in the West |

| Manufacturing Impact | Potentially over $12 trillion industry facing massive disruption |

| AI Integration | Process optimization through artificial intelligence capabilities |

Conclusion

3D printing technology has improved tremendously over the past decade alone. Experts predict even more radical advancements by 2030 and beyond, as precision and capabilities skyrocket while costs plummet. From bioprinted human organs to household goods printed in one’s living room, 3D printing promises to be an extremely disruptive technology over the next decade. Companies that embrace additive manufacturing early will have a competitive edge in this rapidly evolving landscape. With versatile on-demand fabrication that can produce highly complex and customizable items, 3D printing is poised to transform our world in the coming years through rapid digital manufacturing.