Did you know that the global market for 3D printing products and services might exceed 40 billion U.S. dollars by 2024? This impressive number shows how 3D printing is changing manufacturing and digital fabrication. It makes it possible to create personalized products from digital designs.

3D printing, also known as additive manufacturing, is more than just a new trend. It’s a major step towards innovation in industries. It helps in the fast adoption of 3D printed products. Whether you love experimenting with new technologies or have experience in making custom products, learning about 3D printing is beneficial. There are many 3D printing services and materials out there. Your adventure in this amazing field is bound only by what you can imagine.

Key Takeaways

- The expansive growth of the 3D printing market underscores its pivotal role in modern manufacturing.

- 3D printing technology has democratized digital fabrication, pushing the boundaries of personalized and custom manufacturing.

- Additive manufacturing offers a sustainable approach with minimal waste compared to traditional manufacturing processes.

- A diverse range of industries harnesses 3D printing services for rapid prototyping and creating complex geometries with ease.

- The choice of materials plays a crucial role in determining the function and quality of 3D printed products.

- Continuous advancements in 3D printing offer new opportunities for industrial innovation and the customization of consumer goods.

The Revolutionary Impact of 3D Printing Technology

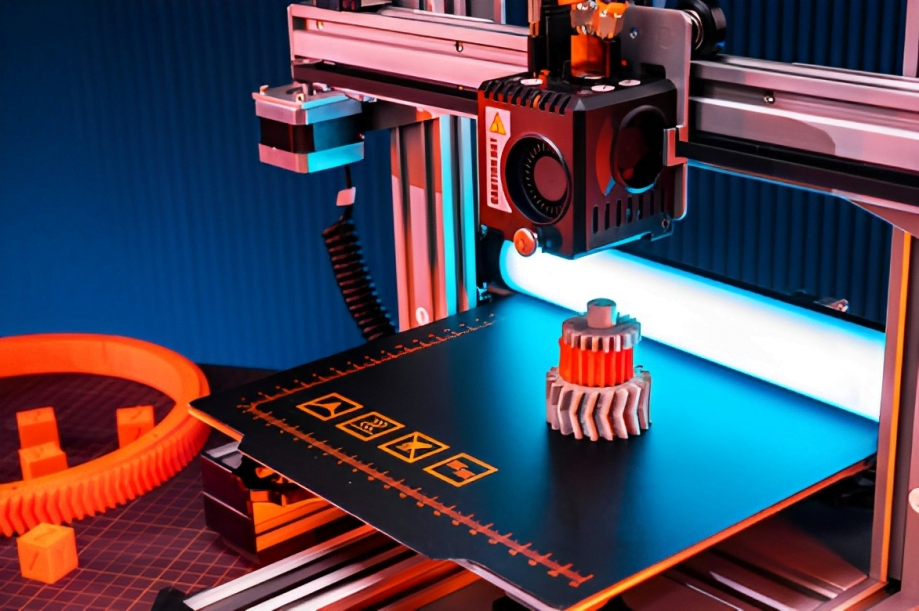

Industrial 3D printing has dramatically changed the manufacturing landscape. The creation process, from idea to product, is faster than ever thanks to rapid prototyping. This means we can now see and touch designs sooner, pushing innovation further.

3D modeling and 3D design have improved how products look and work. They bring ideas to life quickly and efficiently.

In the world of printing technologies, certain methods stand out. Fused deposition modeling, stereolithography, and SLS printing simplify production. They use special techniques and materials to meet different industry needs without raising costs.

| Technology | Key Feature | Material Used | Industry Applications |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Extruded thermoplastic filament | ABS, PLA, Nylon | Consumer goods, Automotive, Aerospace |

| Stereolithography (SLA) | UV laser to cure resin | Photopolymer Resin | Dental, Jewelry, Medical devices |

| Selective Laser Sintering (SLS) | Laser sintering of powder materials | Nylon, Polystyrene, Metals | Complex geometries, High detail parts |

Industrial 3D printing has done more than just improve prototyping. It’s changed how we think about and do production. As we dive deeper into 3D modeling and 3D design, these technologies help create more complex and durable items. They open new possibilities for businesses and creators.

3D Printing: From Concept to Reality

Starting a 3D printing project turns your cool ideas into something you can touch. This journey changes digital designs into real objects. It’s exciting! We’ll look at how 3D printing is changing the way we make prototypes. And we’ll explore the world of digital making.

Understanding the 3D Printing Process

Picture your design taking shape, one layer at a time. That’s what 3D printing is all about. First comes 3D modeling. Here, an idea gets turned into a digital file with special software. This file is then cut into thin layers, guiding the printer. This is different from old-school ways that strip away material. 3D printing adds material layer by layer, cutting down on waste and letting us make complex designs.

Key Technologies Behind 3D Printing

Each 3D printing method has its own superpowers. Fused deposition modeling (FDM) melts plastic to build layers. Stereolithography (SLA) uses a laser to turn liquid resin solid. Selective laser sintering (SLS) melts powder with lasers. These methods are making 3D printing better and more accurate. They’re changing how we move from a first prototype to the final product.

Materials Used in 3D Printing

3D printing can use lots of materials, from tough metals to flexible plastics. Metals are great for heavy-duty jobs. Plastics are versatile for many projects. Nowadays, we can even use ceramics and resins. This lets us do special projects like medical models and unique crafts. The material you pick can affect your project’s look, feel, and performance.

As we use 3D printing in more areas, its potential grows. It’s becoming key for making prototypes fast or crafting complex, personalized items. 3D printing is redefining how we manufacture things.

Conclusion

3D printing is more than an exciting tech journey. It marks a major shift toward personalized manufacturing. This change improves how we think about making things. It also points us to a future where digital fabrication is common. The growth of 3D printed products shows how forward-thinking this area is. It’s dynamic and offers endless possibilities for those who design, engineer, and make goods.

Additive manufacturing changes ideas into real items quickly and accurately. This is something we once thought was unachievable. It affects almost every industry, bringing a new wave of speed and customization. As 3D printing technology gets better, more people can use it. This makes fast innovation vital in today’s market that loves personalized products.

The future of 3D printing is looking up, thanks to more people using it and better technology. It’s building a world where creative, custom solutions are the norm. Getting into 3D printing puts you at the cutting edge of modern making. Here, your visions come to life exactly how you want them. With 3D printing technology, making what you imagine has never been easier or more thrilling.

FAQ

What are the main benefits of 3D printing?

3D printing brings many benefits. It lets us create complex and unique items precisely. It also cuts down on waste by adding materials as needed. With it, products can be developed faster through quick prototyping.

It encourages digital fabrication and tailored manufacturing. This way, it helps in making personalized manufacturing options.

How does 3D printing work?

3D printing transforms a digital model into a real object. First, it splits the model into thin layers. Then, a printer builds these layers from the bottom up. This layer-by-layer method allows for detailed designs that are hard to make with traditional methods.

What industries are using 3D printing technology?

Many fields use 3D printing, like aerospace, cars, healthcare, education, and consumer goods. It’s great for making complex prototypes or custom parts fast. It works well when other methods are too cost-heavy or not doable.

What materials can be used in 3D printing?

3D printing works with many materials. This includes plastics, metals, ceramics, and more. The material choice depends on what the final product needs, like strength, bendiness, or heat resistance.

What is the difference between fused deposition modeling and stereolithography?

Fused deposition modeling, or FDM, builds objects by melting plastic and layering it. Stereolithography, or SLA, turns liquid resin into hard plastic using a laser. FDM is quicker and cheaper. SLA offers finer details and smoother surfaces.

Can I use 3D printing for mass production?

Yes, 3D printing isn’t just for making prototypes anymore. It’s being used more for making lots of products. This is especially true for items that need to be unique or very detailed. New developments in this tech make it more possible every day.

How has 3D printing changed the manufacturing industry?

3D printing has made a big impact on making things. It’s sparked new industrial ideas and can make products with complex designs. It speeds up creating things and cuts down costs. It’s also opened doors for making products tailored to specific needs.

What software is needed for 3D printing?

For 3D printing, you need special software. This includes tools for designing in 3D and others for splitting the design into layers. Good examples are CAD software for design and slicer programs for preparing the model for printing.

What are selective laser sintering (SLS) and its applications?

Selective laser sintering, or SLS, is a way to print by sintering powder into solid shapes. It uses materials like nylon. This method is good for making tough parts with intricate designs. It’s used in many areas, including aerospace and automotive.

How can I access 3D printing services?

You can get 3D printing services from companies focused on digital fabrication. These companies have online sites where you can upload designs, pick materials, and options. They will print your designs and send them to you. Their services are open to everyone, from individuals to big companies.