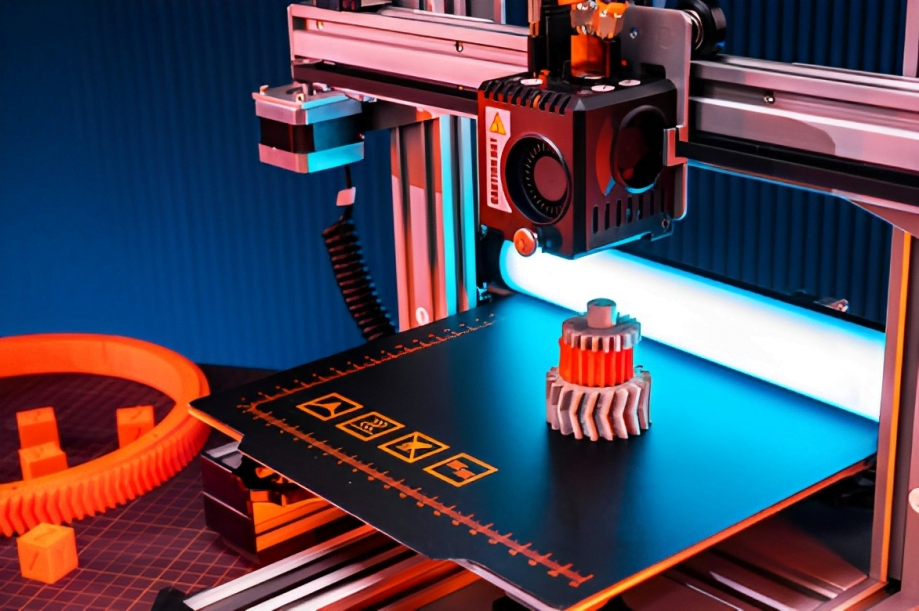

Did you know the global market for digital fabrication is on the rise? It suggests a major shift in manufacturing is happening right now. 3D printing technology and automated manufacturing are changing industries fast. This article looks into digital manufacturing, where precision and innovation create the future of production.

The power of Industry 4.0, artificial intelligence (AI), and the Internet of Things (IoT) make digital fabrication the new norm for smart manufacturing. Combining computer-aided design (CAD) with additive manufacturing has led to amazing achievements. For instance, take the groundbreaking architecture in Dubai. Computer-assisted design and advanced manufacturing are more than buzzwords. They’re tools turning ideas into reality.

With today’s technology, your imagination sets the limits. Let’s look at what makes digital fabrication special and how it opens new paths. Get ready to be wowed by what this field can do. From smart walls you can touch to merging ecology with design, the journey is thrilling.

Key Takeaways

- Grasp the growing impact of digital fabrication on the global manufacturing landscape.

- Learn about smart manufacturing techniques that change production with AI and IoT.

- Discover how 3D design and 3D printing technology shape tomorrow’s structures.

- Uncover the link between computer-aided design (CAD) and additive manufacturing in new projects.

- Recognize the role of advanced manufacturing in the Industry 4.0 era.

Digital Fabrication: Revolutionizing Product Design and Manufacturing

The world of digital design is changing. It’s shifting the base of product design and manufacturing. With computer numerical control (CNC) and computer-aided manufacturing, we’re seeing new levels of automated production and custom work. If you’re curious about its impact, look at TEX-FAB’s award-winning architectural designs. They showcase this technological leap.

| Technique | Application | Advantages |

|---|---|---|

| 3D Printing | Architecture Model | Precision in complex geometry |

| Parametric Design | Innovative Design | Dynamic adaptability |

| CNC Machining | Sculptural Design | Detail in large scale production |

Think about using a 3D printer to create a complete architecture model. Or how parametric design can make structures that react to people. This is happening in places like F.A.D.S + fujiki studio’s breathable Japanese tearoom in Tokyo. Digital tools are reshaping the blend of beauty and function in sculptural design.

Your capacity to produce groundbreaking work in an array of materials hinges upon these technological advancements.

We’re not just talking ideas; it’s about making real, customized objects and spaces with innovative design. The mix of tech and creativity is shaping the future of product design.

- Computer Numerical Control (CNC) offers unsurpassed control and efficiency for customized products.

- Digital Design techniques pave the way for challenging the status quo of traditional crafting.

- Automatic Production systems enhance the capacity to produce with both speed and quality.

At its core, blending digital tech with creative design is not just changing the industry. It’s pushing the boundaries of imagination and creation.

The Expanding Universe of Additive Manufacturing and 3D Printing

The dynamic world of additive manufacturing is changing the game. The mix of 3D printing and digital design is making a big shift in how we do architectural projects. Using computer-aided design (CAD) and 3D printing, our ideas can become real in new ways.

Breakthroughs in 3D Printing Technology

New materials like Digital Wood are making a big splash. Now, rapid prototyping is a key part of design. Projects from global competitions are showing the power of 3D printers. They turn complex designs into real, amazing architectural models.

Rapid Prototyping: From Idea to Reality

Now, parametric design software is key for 3D printing. It lets architects and designers quickly change and perfect their ideas. This tech breaks free from old limits, making once impossible structures real, fast.

Environmental Impact of Additive Manufacturing

Additive manufacturing also cares about the planet. As we aim for greener production, the role of 3D printing is big. It brings less waste and more resource efficiency, showing what green innovation looks like.

| Aspect | Traditional Manufacturing | Additive Manufacturing |

|---|---|---|

| Design Complexity | Limited by tooling constraints | Unbounded potential |

| Speed to Market | Extended lead times | Rapid prototyping and iteration |

| Environmental Impact | Higher waste and resource use | Resource efficiency and less waste |

| Sustainable Practices | Challenging integration | Inherent in process |

In the growing world of 3D printing, dreams turn into real spaces. It shows technology can be green and creative. Here, being eco-friendly is a must.

Automated Manufacturing: CNC Machining, Laser Cutting, and CAD

The use of CNC machining together with laser cutting has changed how things are made. It allows for creating items with amazing precision manufacturing. This has brought us faster and more correct results than before. These methods are key in today’s computer-aided design and computer-aided manufacturing. They lead the way to better, more reliable, and adaptable ways of making things. Let’s look at how these technologies are changing the manufacturing world.

- CNC Machining: A key part of digital fabrication, CNC machining works with amazing detail. It shapes materials to match specific requirements, making sure everything meets today’s high standards.

- Laser Cutting: This is famous for its ability to make detailed cuts. Laser cutting helps CNC machining by making clean, exact cuts in many materials. This improves what we can make with custom fabrication.

- Computer-Aided Design: CAD stays at the core of making things automatically. It helps with complex designs that turn into real things easily, saving time and reducing mistakes in making products.

With these advanced tools, makers can handle very detailed projects. They provide solutions that match exactly what their customers want. Mixing CNC machining, laser cutting, and computer-aided design together works well. It creates a combination that is important for making things in new and better ways. So, the items produced are not just made — they are crafted with precision.

Modern manufacturing is not just about making lots of things. It’s about paying attention to every detail. This leads to precision manufacturing of unique items.

Conclusion

Reflecting on digital fabrication shows its huge impact. It’s a mix of modern engineering and creative freedom. The world of 3D printing and automated manufacturing is changing production. It combines precise work with big ideas. Your part in this change is key. Whether you’re buying, designing, or making, you help bring new possibilities to life.

Digital tools like CNC machining and laser cutting have changed how we make things. They make work faster and more personal. Companies using these tools are ahead of the game. By embracing these technologies, you stay relevant. You also become more flexible in a fast-moving market.

There’s a big push for sustainable manufacturing. It’s good for the planet and shows how the industry can grow without harm. Using these green methods is becoming more common. By doing so, you’re not just helping the economy. You’re also making the world a better, more sustainable place. Let’s move into a future where digital tools lift us all higher.

FAQ

Q: What is digital fabrication and how does it relate to Industry 4.0?

A: Digital fabrication is about creating products with automated, digital tools like 3D printers and laser cutters. It’s a big part of Industry 4.0, or the fourth industrial revolution. This revolution is about smart manufacturing that uses automation, data exchange, and artificial intelligence.

The shift to using technologies such as computer-aided design (CAD) is making production more efficient and innovative.

Q: How does digital fabrication revolutionize product design and manufacturing?

A: Digital fabrication brings new ways to design and make things using tools like CNC and 3D printing. It lets us create designs that would be hard to make the old-fashioned way. Now we can make intricate and complex designs with ease.

Designers can use these advanced technologies to make custom and innovative products quickly. This opens up opportunities for more personalized products.

Q: What are the latest breakthroughs in 3D printing technology?

A: Recent advances in 3D printing include new materials like programmable biocomposites. There’s also been a push towards making things that can change or respond, like breathing walls. These improvements are leading 3D printing into areas like large construction and precise prototyping.

Now, we can use 3D printing for making detailed architectural models, efficient construction parts, and tailored medical devices.

Q: How is rapid prototyping integral to digital fabrication?

A: Rapid prototyping is key in digital fabrication as it turns ideas into physical objects fast. Using digital designs and 3D printers shortens the development process. This allows for testing and improving designs quickly.

It’s crucial for refining designs and making functional prototypes. This process is highlighted in digital fabrication contests and academic work.

Q: What role does additive manufacturing play in sustainability?

A: Additive manufacturing is important for sustainable production as it reduces waste. It builds objects layer by layer, using just enough material. This is better for the environment and supports greener production methods.

By focusing on using materials wisely, additive manufacturing fits well with sustainable manufacturing goals.

Q: How do CNC machining and laser cutting fit into the automated manufacturing process?

A: CNC machining and laser cutting are essential for automated manufacturing. CNC machining makes precise metal parts and components. Laser cutting is great for fast, accurate cuts in many materials.

Both are controlled by computer-aided design (CAD) data, which guarantees high accuracy. These technologies help make efficient, custom designs possible.